Editor’s Note: Today, the final installment of The Greatest Horological Inventions of All Time. Here, Andrew Canter examines the story behind the co-axial escapement, invented by George Daniels, industrialized by Omega, and now considered one of the great watchmaking innovations of all time.

You can find more of Andrew’s work at the Mr. Watchmaster website here.

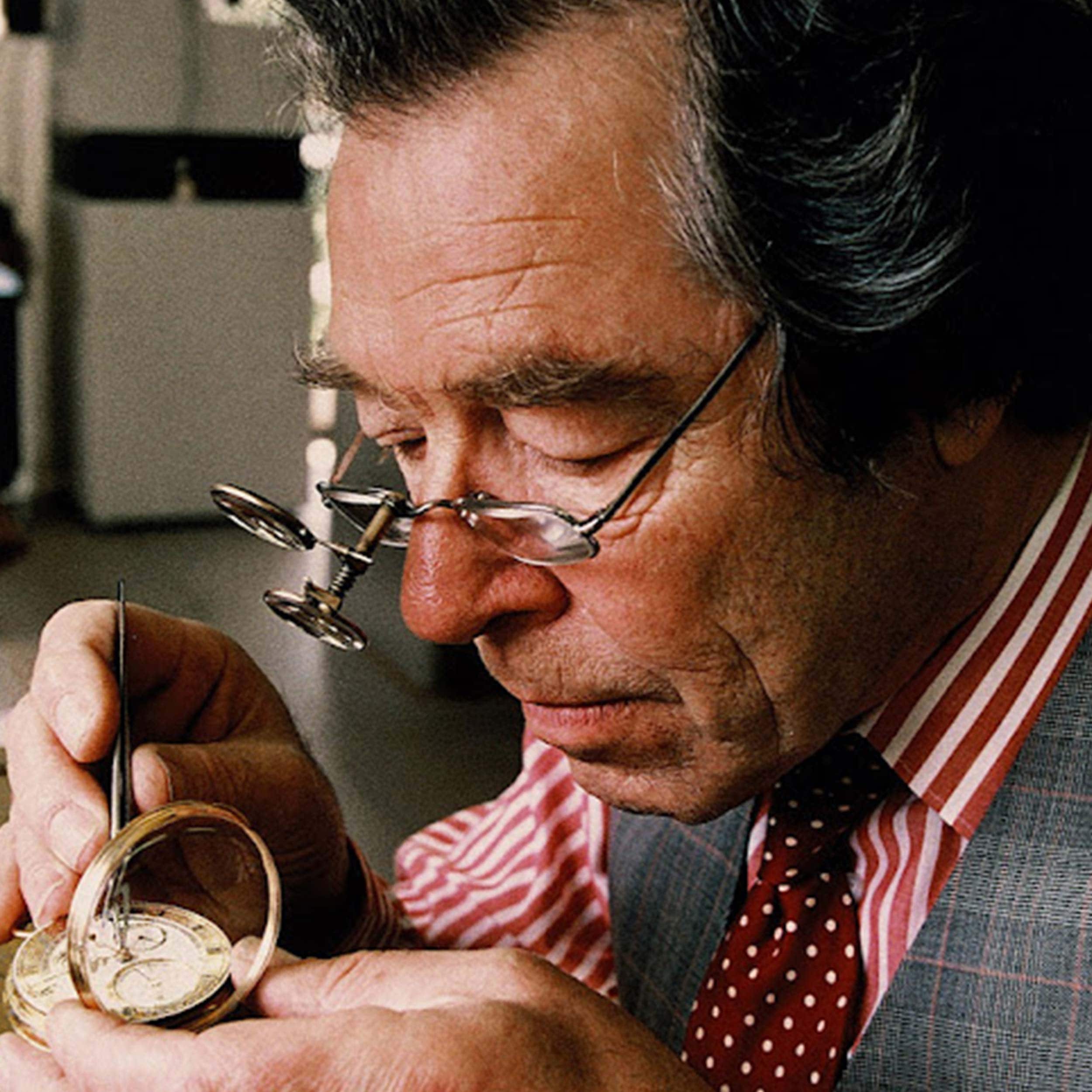

George Daniels (1926 – 2011) was raised in London in poverty. Aged five, he pried open his family’s alarm clock and realised that it was a metaphor for his life – always moving inexorably onwards, but without outside assistance. He was determined to learn horology, despite his parents’ opposition. He was conscripted into military service in 1944 which unleashed his innate mechanical skills, and following the end of the war, he studied horology, while repairing watches in North London.

He gained access to the work of the greatest watchmakers, particularly Abraham-Louis Breguet, through a meeting with a collector, and when it seemed that quartz technology would overwhelm traditional watchmaking, Daniels ensured this would not come to fruition. He made a series of increasingly ingenious mechanical watches, heavily influenced by Breguet, teaching himself to make every part, now referred to as the ‘Daniels Method’. Essentially, he devised a virtually oil-free escapement – the now iconic co-axial escapement – which was later mass-produced by Omega.

It was anything but an easy journey, but George Daniels is considered by many to have been the finest horologist in the world during his lifetime. Perhaps his greatest contribution to the art of watchmaking was to develop his co-axial escapement, which revolutionized mechanical watchmaking and is often described as the most important horological invention for over two hundred and fifty years.

“The quartz watch is entirely dependent on its battery, and it has the dedicated ambition to commit suicide as soon as possible.”

George Daniels, Master Watchmaker

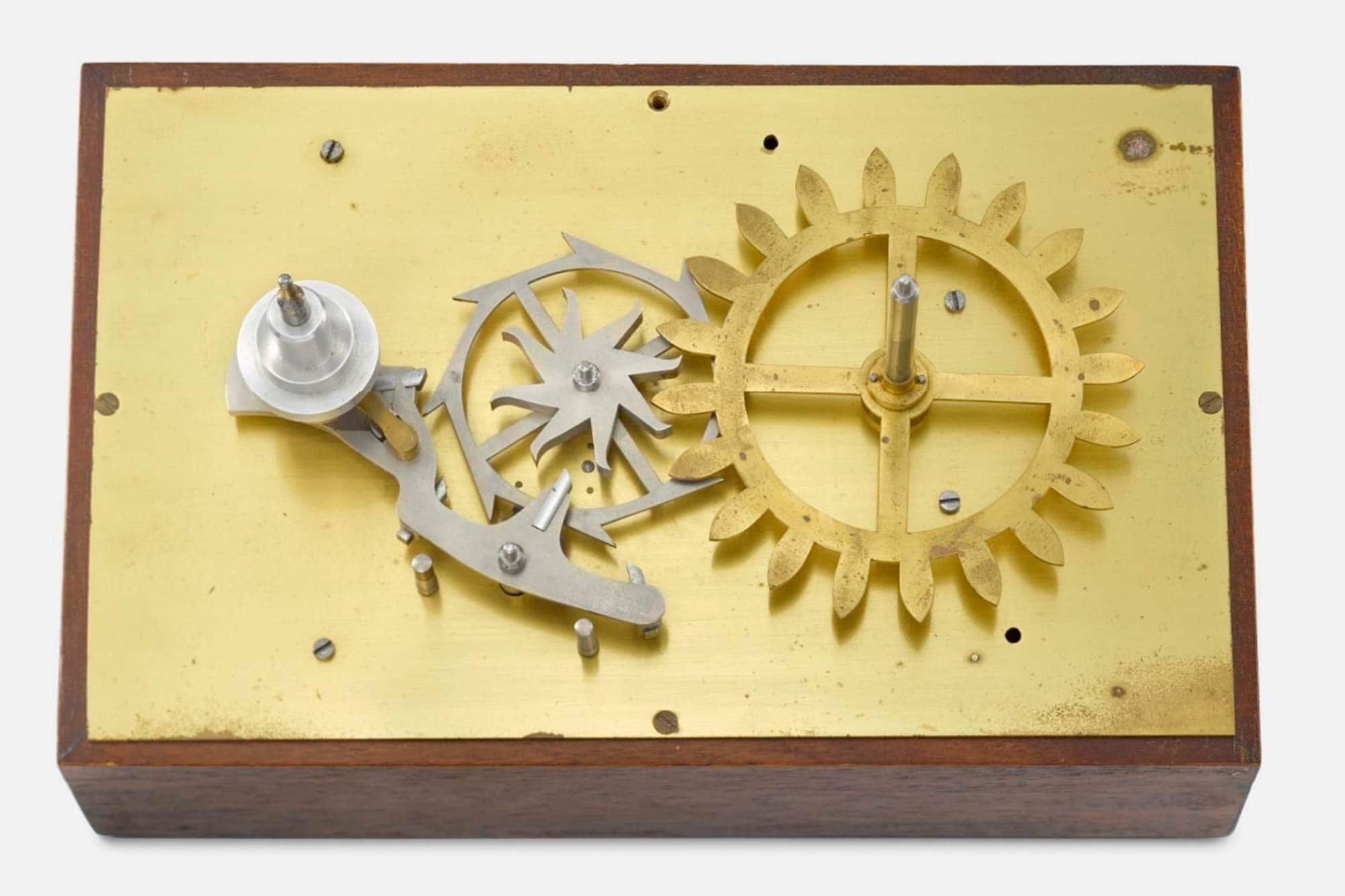

It was in 1974 that Daniels had completed designs for the most successful of his revolutionary escapements, the ‘Daniels Co-axial’. This escapement represented the greatest advancement in mechanical movement design since Thomas Mudge invented the lever escapement in 1754. Its success lies in the divergent impulse and lock in both vibrations of each oscillation without sliding friction which, unlike the conventional lever escapement, remain unaffected by changes in viscosity of the lubricant.

Working model of the co-axial escapement built by George Daniels, Isle of Man, c.1985. The Clockmakers’ Museum-Clarissa Bruce © The Clockmakers’ Charity

How the Co-Axial Escapement Works, and Key Features and Benefits

Escape Wheel: The escape wheel rotates and interacts with the co-axial wheel.

Co-axial Wheel: Positioned on the same axis as the escape wheel, it transmits energy through radial and lateral impulses.

Lever: The lever interacts with the co-axial wheel and pallets to control the release of energy to the balance wheel.

Ultimately, the co-axial escapement minimises sliding friction between the components, which is a significant source of wear and energy loss in traditional lever escapements. It uses a combination of radial and lateral impulses to transfer energy, which reduces the need for lubrication.

By reducing friction and wear, the co-axial escapement improves accuracy and helps maintain more consistent timekeeping over a longer period. It also contributes to greater long-term accuracy of the watch. With less friction and reduced need for lubrication, watches with a co-axial escapement require less frequent servicing compared to those with traditional escapements.

The co-axial escapement typically includes a three-level system comprising an escape wheel, a co-axial wheel, and a lever. The escape wheel and the co-axial wheel are mounted on the same axis, hence the name ‘co-axial’.

“I knew immediately that my invention was superior to all the others.”

George Daniels, Master Watchmaker

After extensive and rigorous testing, the results were extremely positive and, following a twenty-five-year campaign, found international support in the notoriously conservative watch industry.

The Implementation of the Co-Axial Escapement

Omega, was the first and remains the primary user of the co-axial escapement, having adopted and industrialised the technology in the late 1990s. The mechanism is now a hallmark of Omega’s high-end timepieces, emphasising precision and durability. But it didn’t start that way, as Daniel’s offered the movement to other manufacturers, including Rolex and Patek Philippe.

Prototype watch movement with Co-axial escapement by Patek Philippe, Switzerland, c.1981. Courtesy of The Clockmakers’ Museum/Clarissa Bruce © The Clockmakers’ Charity

This is a prototype watch movement with Co-axial escapement made by Patek Philippe in Switzerland (c.1981). It is one of three exceptionally slender wristwatch movements with co-axial escapements, made by the Research and Development Department of Patek Philippe, to assess George Daniels’ escapement’s performance. In his autobiography, George Daniels explains that these movements were not made according to his recommendations and were therefore not a success. This really sums up Daniels’ relationship with the Swiss watch manufacturers which resulted in them generally disagreeing about the value of the co-axial escapement.

Oldest wristwatch with a co-axial escapement, by Patek Philippe and George Daniels. Science Museum Group/The Clockmakers’ Museum © The Board of Trustees of the Science Museum

However, Daniels’ did manage to get the co-axial into a Patek Philippe watch as the movement of this production wristwatch was converted to include it in 1981, at the request of Patek Philippe. It was fitted with a case and dial in Switzerland and returned to him by early 1982. He wore it continuously for ten years, during which time the escapement performed well, without the need for attention. Subsequently it is now the oldest co-axial wristwatch in existence.

Everything changed in the late 1990s, when a new generation of watchmakers came to the fore who were full of admiration for Daniels’ work. It was at this time that Nicolas G. Hayek, CEO of the powerful Swatch Group, acquired the rights to the co-axial escapement for the Omega brand. The rest as they say is history, as in 1999, the first series of watches was launched.

Early Omega De Ville wristwatch with Co-axial escapement. Science Museum Group/The Clockmakers’ Museum © The Board of Trustees of the Science Museum

This limited-edition Omega De Ville automatic wristwatch was the first mass produced watch to use George Daniels’ co-axial escapement, launched as a limited edition of 999 pieces.

Advantages of the Co-Axial Escapement Over Traditional Escapements

- Less Lubrication – traditional lever escapements require regular lubrication to function smoothly. The co-axial escapement’s design reduces the dependence on lubrication.

- Durability – less friction means the parts of the movement experience less wear, leading to a longer lifespan.

- Energy Efficiency – the efficient transfer of energy enhances the watch’s overall performance.

“You don’t wear a watch just to tell the time, but also so that you can touch it and distract yourself with it when you’re sitting in a tedious meeting.”

George Daniels, Master Watchmaker

In 2010, George Daniels’ created a series of watches, utilising his own design of the hand-made co-axial movement, produced in-house on the Isle of Man. He approached Roger W. Smith with a proposal and so, 35 years after the invention of the Co-axial, they formed a collaboration to produce the ‘Co-Axial Anniversary’ wristwatch (above). This stunning timepiece serves as a lasting legacy to the ‘Father of English Watchmaking’ as does every Omega watch containing the extraordinary Daniels co-axial escapement.

In summary, the Daniels co-axial escapement represented a significant advancement in horology, offering improved accuracy, reduced maintenance, and enhanced longevity, making it a sought-after feature in luxury mechanical watches.

The post The Greatest Horological Inventions of All Time: Why George Daniels’ Co-Axial Escapement Revolutionised Mechanical Watchmaking appeared first on Worn & Wound.